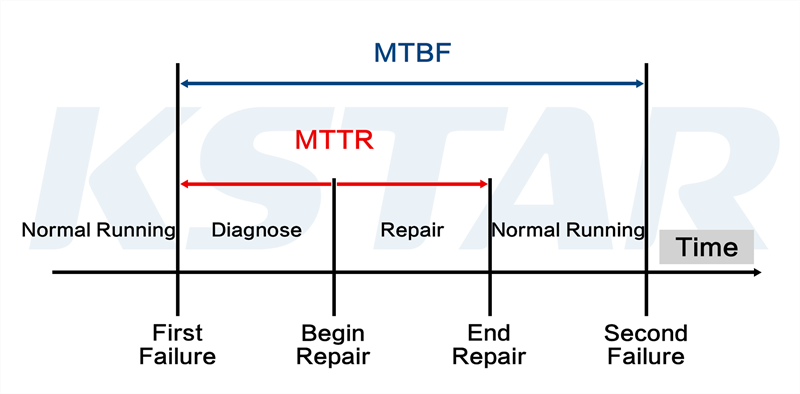

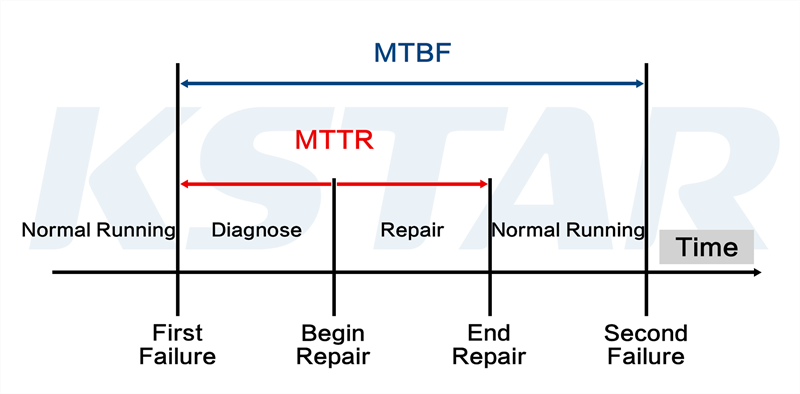

Product reliability is very important. This is why you need failure indicators such as MTBF, MTTR to help you measure product reliability. Before using them effectively, you need to know what meaning hides behind their acronyms, how to distinguish between them, and what does that tell you about your equipment.

MTBF Meaning

MTBF is short for

“Mean Time Between Failure”. It means the average time between the innate failures of machinery during normal operation hours. MTBF is a measure of the reliability index of a product (especially electrical products).and it is usually measured in hours.

Still confused about the meaning of MTBF? Hope the following

MTBF calculation formula with a simple example can help you better understand the concept.

MTBF Calculation

To calculate MTBF, divide the total time of correct operation in a period by the number of failures that occurred in that period.

Formula: MTBF=Total time of correct operation in a period/Number of failures.

For Example:

A generator that is expected to work for 24 hours a day has three outages. One lasts for 2 hours, another for 3 hours and the final breakdown lasts for an hour.

Then,you can get the information as below:

1.Total correct operation time=Total working time(24 hours)-total breakdown time(2+3+1 hours)=18hours

2. Number of breakdowns=3 times

So the Mean Time Between Failures calculation will be:

MTBF=18 hours/ 3 times=6 hours

MTBF is an indication of reliability and availability, it does not represent the lifespan of the product. For Example: If an online UPS has an MTBF of roughly 100,000 hours, it means the UPS has high reliability.

MTBF vs MTTR, What's the difference:

In short, MTBF helps you predict how long an asset can run before the next unplanned breakdown happens while MTTR tells you how long it takes to fix the unplanned breakdowns.

MTTR meaning

MTTR is short for Mean time to repair. It is a metric used to measure the average time between the issue arising and the system becoming available for use again. It includes the time required for the following steps: Notification-Diagnosis-Fix-Reassemble-Test-Start up.

The same as before, I will tell you how to

calculate MTBF with a simple example.

MTBF Calculation

To calculate MTTR, you should the total unplanned maintenance time by the total number of repairs (failures).

Formula: MTTR= Total unplanned maintenance time/Total times of repairs

For example:

A UPS broke down 3 times throughout a year. The first breakdown cost you 4 hours to repair, the second time cost you 3 hours while the last time 2 hours. In that case, MTTR would be 9 hours / 3 times = 3 hours.

MTTR helps you to increase efficiency and limit unplanned downtime. Imagine if your repairs is longer than the MTTR of the equipment, you may make an analysis and figure out why. My team used to lack parts for repair, which expand the repair time and it occurs regularly. We decide to purchase spare parts for certain parts after the MTTR analysis.

In a word, both MTBF (Mean Time Between Failures) and MTTR (Mean Time To Repair) are two very important indicators when it comes to availability of an application. Make good use of it will help you and your Maintenance team to improve the efficiency as well as performance of the processes.